The idea of a new product launch no longer seems like a novelty. However, there continues to be a high expectation from these businesses as they continue to evolve their product lines and extend their existing capabilities.

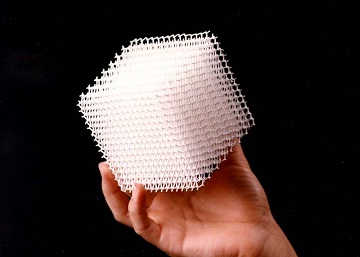

While consumers enjoy using new products and appreciate forward-thinking companies, designing, refining, testing and delivering new products to the market can be an expensive undertaking if no one is watching the pocketbook or the time clock. This makes rapid prototyping a very attractive technology that evolves right along with new designs.

Saving money through simulation

Rapid prototyping allows the designer to see what the final product might look like. More importantly, the designer, engineer and end user can interact and see the most critical functions at work through simulation. This can all take place without actually creating the final component.

Now, designers are making improvements early in the life cycle and at every step in development. This saves money in development simply because refinements can happen before any final production commitments and expenses are made.

What’s more valuable than money? How about time.

Fixing design flaws prior to production can eliminate the production of faulty parts. This reduces testing time, while the improved part comes to life within a software package, instead of through slow iterations on the factory floor. Fewer flaws throughout development can lead to a better end product and a more satisfied customer in a shorter amount of time.

Rapid prototyping is a fast-evolving technology, but the basic principle of product and development without physically creating expensive parts remains at the foundation of production. If you’re developing products without it, you’re wasting valuable time and money.

Product Development Solutions understands what challenges you face as a business. Whether you’re looking to boost sales with a new product or would like to increase your turnaround time, we can help. Call PDS today for a fast quote on your next project.