Project Showcase

Medical production parts & assembly

A global healthcare manufacturer contracted PDS to develop and test a new MRI compatible assembly. This low volume fully functional medical assembly consists of multiple different piece parts. PDS provided CNC machining, painting, and 100 assembled units in less than three weeks.

A global healthcare manufacturer contracted PDS to develop and test a new MRI compatible assembly. This low volume fully functional medical assembly consists of multiple different piece parts. PDS provided CNC machining, painting, and 100 assembled units in less than three weeks.

The assembly was designed for injection molding, but the tooling cost and lead-times were prohibitive. Using the latest high speed horizontal and vertical milling centers PDS was able to help the customer achieve competitive prices and fast, flexible lead times.

Starting with SLA and FDM prototypes we were able to semi functionally test the parts and then make some minor tweaks to the fit, form, and function. After reviewing and testing the prototype parts, some parts needed to be modified. PDS then modified the design and provided CNC machined, painted, and decorated parts from the spec material for final testing. The customer chose to use machining as their production process due to the fact that PDS was able to provide a cost effective solution for the low volume production runs.

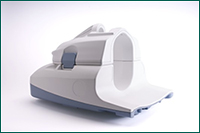

Cast Urethane Medical MRI Assembly Housing

This customer was able to use PDS’s Short-Run Production capabilities to get the parts they needed and keep up with demand in a cost effective manner while keeping manufacturing in the U.S.

This customer was able to use PDS’s Short-Run Production capabilities to get the parts they needed and keep up with demand in a cost effective manner while keeping manufacturing in the U.S.

- Quantity 10 prototypes 150 production units per year

- Material: TD277-02 Cast Urethane

- Lead-time 17 working days

CNC Machined 6061 Aluminum multiple components for production

Customer needed parts prior to permanent molds being completed. PDS strives for excellence as a prototype and bridge-to-production manufacturer.

Customer needed parts prior to permanent molds being completed. PDS strives for excellence as a prototype and bridge-to-production manufacturer.

- Quantity 500

- Material 6061 Aluminum

- Lead-time: 1st parts in 6 working days order complete in less than 4 weeks

CNC Machined Handle – Large part made out of exotic material

Customer needed to drop test a new design for verification. This exotic metal part was large with complex features that can be attained via our in-house 4-axis horizontal CNC mills.

Customer needed to drop test a new design for verification. This exotic metal part was large with complex features that can be attained via our in-house 4-axis horizontal CNC mills.

- Quantity 15

- Material: Magnesium

- Lead-time 15 working days

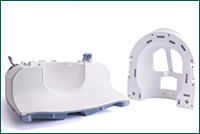

MRI Assembly using numerous different technologies

These two items, a 16 Channel and 32 Channel MRI Housings contain numerous Rapid Technologies to produce these functional pieces.

These two items, a 16 Channel and 32 Channel MRI Housings contain numerous Rapid Technologies to produce these functional pieces.

The 16 Channel piece has:

- 10 urethane components

- 21 CNC machined components

The 32 channel has:

- 10 urethane components

- 17 CNC machined parts

- 1 injection molded part

They both include:

- SLA/PolyJet patterns for RTV Molds

- CNC machined patterns

- RTV Molds to create cast urethane parts

- Brass inserts cast into place, thus no secondary inserting or gluing inserts were necessary

- CNC machined parts made from Delrin Polycarbonate Mirrored acrylic

CNC Machined Impeller

Customer needed parts for testing prior to production. Although a small quantity, the customer was able to use these prototypes that were equal in properties and tolerances to their production parts to prove out their design and functionality in this CNC machined impeller.

Customer needed parts for testing prior to production. Although a small quantity, the customer was able to use these prototypes that were equal in properties and tolerances to their production parts to prove out their design and functionality in this CNC machined impeller.

- Quantity 10

- Material 6061 Aluminum

- Lead-time 10 working days