All the coverage and attention given to 3D printing technologies makes it seem like the future of production is shifting. Like any other budding technology, 3D printing has its advantages and limitations too.

Instead of adding material, take it away

CNC machining represents the older, well-tested brother to 3D printing and it often gets overlooked when you hear of the experts in the field of “digital manufacturing.” The fact of the matter is that CNC machining techniques received the digital treatment long before 3D printing, and it fits in with any manufacturing environment.

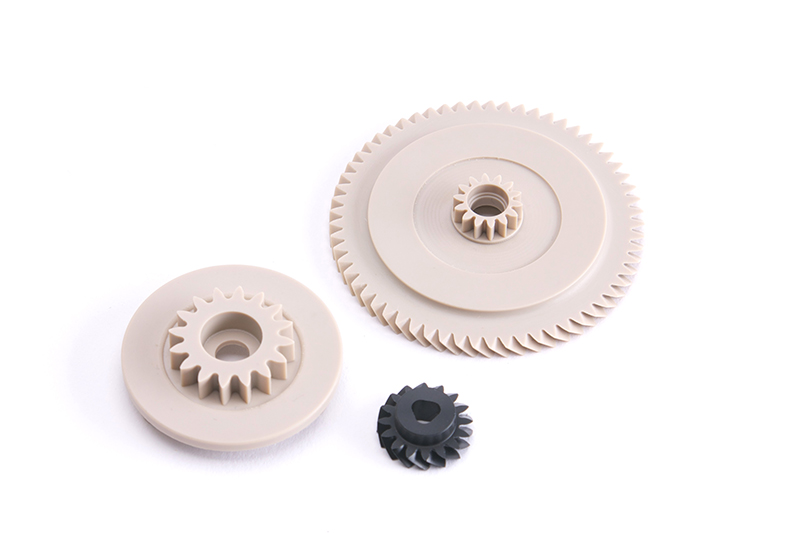

In many cases, taking material away to create an object is more efficient than waiting for layers to form in a 3D printing process. Just to review, CNC machines work by taking a solid block and carving away the unneeded pieces, usually with drills and cutting tools.

CNC machining advantages

- Material choices are almost limitless. If it can be cut or drilled, it will most likely work. Some machines may not handle steel or stone, but any machine can handle a wide range of materials.

- More rigid materials work well, and this is advantageous if you’re looking for a high-quality surface finish.

- The thickness of the layers in a 3D printer can limit the amount of detail in a part. Machining your parts can give you more flexibility.

- Owning and operating a CNC machine is very cost effective compared to many manufacturing systems when you consider how long they last and how easily they can be upgraded.

- The price of a machined part is independent of its size. Large components can be completed just as quickly as a smaller part, depending on the detail.

Many manufacturing facilities find valuable uses for both production technologies, but it’s a big mistake to disregard the tried-and-true service offered by CNC machining. Sit down with an experienced pro from Product Development Solutions, and explore your best options with a quick quote.