Lighter aircraft, reduced fuel consumption and an easier path towards mass production are just a few of the benefits manufacturers are reaping from 3D printing. So, it’s to no one’s surprise that this technology is taking the aerospace industry to new heights.

In a flash, 3D printing has gone from a science-fiction-like, “wouldn’t-it-be-great-if” concept to a viable and dependable way to produce intricate and sophisticated parts and components for the aerospace industry. As a result, the major players are taking advantage of this new technology.

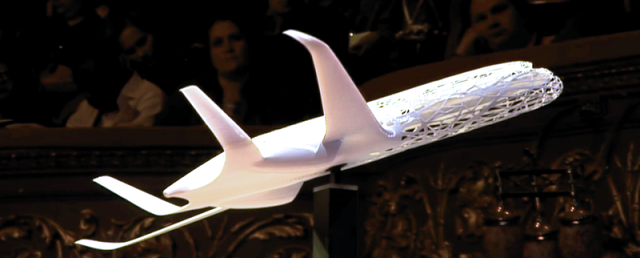

Bastian Schaefer, the cabin and cargo innovation manager at Airbus, has begun imagining high-concept jet airplanes of the future. His vision includes an airplane with a large, rivetless frame that’s full of space and light and is “printed” from the bottom up. The plane of the future would have larger seats that conform to the passenger’s body, social areas where a person can play virtual golf, and large windows that give everyone aboard a view of the skyline.

Schaefer’s 3D printed jumbo jet sounds like something from a science-fiction movie, but it’s not. Airbus is already producing components using 3D laser printers. The company’s new cabin mount, engineered using “bionic designs” and made of titanium, is half the weight of a conventional component — and every bit as reliable.

In fact, Airbus says that 3D printing can reduce the weight of components by up to 70 percent and can actually result in parts and components that are sturdier than those manufactured using more traditional methods.

Of course, a 3D-printed part is only as good as its prototype, which is why the aerospace industry is leaning so heavily on manufacturing companies with the ability to develop world-class prototypes using machining and cast urethane processes.

The cast urethane process starts with the computer-aided design, or CAD file. Once the file meets the exact specifications, CNC machining is used to make a master that’s finished with precision. It’s a process that allows engineers to create lighter, more precise parts, and then mass produce them using 3D printing.

Like 3D-printed airplanes, developing prototypes with CNC machining is a fast process you can get a jump on with PDS today.