Plastic or metal? That’s the age-old question manufacturers have wrestled with since Jons Jacob Berzelius unveiled the first condensation polymer in 1847.

Today, the answer is clear — plastic. Plastic manufacturing services are the most sought-after by companies producing reliable parts. When the benefits of plastic are considered, it’s easy to see why.

It’s less expensive. One of the key benefits of using a plastic manufacturing service is that more parts can be made per hour. The injection molding process cycle time is faster, so stamping and casting die-cast parts all cost less to produce.

It saves time. Unlike steel and other materials, there’s no need to spend a lot of time finishing plastic parts. Plastics can be dyed before they’re added to the mold, eliminating an entire step in the production process.

It’s durable. When it comes to structural strength, plastic leads the way. It’s strong, light and easy to use. It also allows for built-in ribs, gussets and bosses during the actual production process. Steel, on the other hand, often requires additional fastening, welding or glue — all of which can make the product less durable.

It’s recyclable. Plastic is versatile. Once the product is no longer functional for its originally intended use, it can often be re-purposed and used to make other parts. This is good for a company’s bottom line, as well as the environment.

It gives products a longer life. It’s not a commonly known fact, but it’s true that most plastics have a higher chemical resistance than metals. This means the product will last longer. It also isn’t susceptible to rusting or oxidizing.

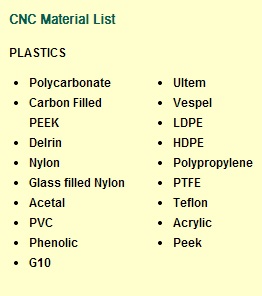

Yes, the answer to the decades-old question of plastic or steel has been answered, which is why more and more products are being developed from plastic. Now, the only remaining question seems to be which plastic is right for your particular project. Contact PDS today to find out!