A well-designed product will leave people burning with anticipation and potential customers dying to buy immediately, but don’t forget to finish the job.

If performed by a trained professional, a top-notch finish will add appeal, quality and longer life to your best product line. No product development process is complete without selecting the best finish for the job.

A comprehensive manufacturing service provider will offer a variety of finishes, efficient processes and the expertise to apply it the right way. Don’t overlook your finishing options.

Hand finishes

Hand finishes, including BeadBlast, deburring, polishing or custom finishes tailored to the customer’s specifications will go a long way toward selling a new product. And when you’re dealing with a short-run prototype, it’s the best way to make an impression while delivering a prototype that’s as close to the finished product as possible.

Coating finishes for plastic and other materials

- Custom painted parts

- Multi-color painting processes

- Rubberized painting

- Heat-treated pieces

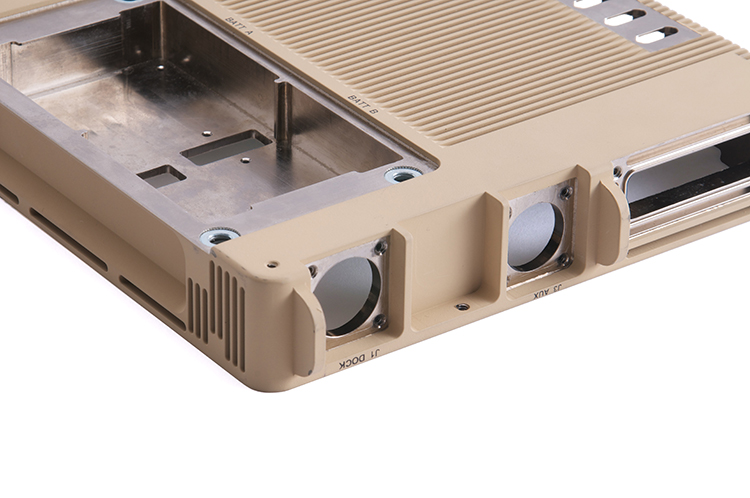

Plating options that offer superb protection for metal

- Anodized metal for strength and protection in corrosive environments

- Nickel chrome for a bright finish

- Titanium

- Teflon

Personalized finishes

- Silk screening

- Pad printing

- Labels

- Laser engraving

Providing a prototype or product with a professional finish sends a message that your company pays attention to the details and has a commitment to producing quality products. Additionally with plating, durable paint and polishes, you can add another layer of quality to a part that will stand up to harsh operating environments, moisture and corrosion. It’s not just about looking pretty.

Product Development Solutions employs experts who specialize solely in the finish of your product. Our trained professionals can apply finishes that will last through years of wear and tear. Get a fast quote today to see where you stand in the prototyping process.