Everyday, medical equipment manufacturers face the challenge of producing incredibly intricate and sensitive products at low numbers. Oftentimes, this means having to create expensive equipment with a high price tag, while facing a merciless and constantly changing marketplace that demands innovation to move life-saving technology forward.

As such, producing precision equipment fast and efficiently is a must for medical equipment manufacturers.

A customer challenge for PDS

Recently, a manufacturer came to PDS to develop a new MRI assembly. This medical equipment producer was drawn to PDS for our ability to keep costs low on short-run production, while still delivering parts quickly and efficiently.

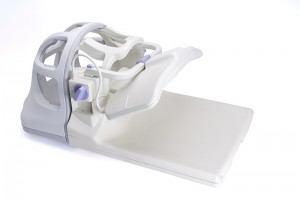

What they presented was a project that included multiple components in a fully functional medical assembly. PDS provided CNC machining, painting services and 100 completed units in under three weeks.

Taking a better approach

Tooling costs proved too high for injection molding, so the staff recommended high-speed horizontal and vertical milling with CNC machinery. This reduced costs with an improved turnaround, while offering flexibility on lead time.

PDS also provided reliable testing with stereolithography and fused-deposition modeling to render semi-functional parts. After a few tweaks to ensure proper fit and minor modifications, PDS produced several CNC machined and painted parts for final testing.

Finishing the job

Convinced that CNC machining was the best path forward, PDS worked with the client to reach a cost-effective solution for low-volume runs that could still deliver components on time. Production demands included 10 prototypes and 150 production units per year with a slim lead time of 17 working days.

The entire assembly included not only urethane components, but machined aluminum and magnesium. In the end, the finished product consisted of 10 urethane components and 21 machined parts. Additionally, another product consisted of 10 urethane components, 17 CNC machined parts and a single injection molded piece. Everything was produced in the United States.

Delivering complex projects inexpensively with a fast turnaround is what our experts at PDS truly excel at. Bring us your toughest project and we can show you the best approach.