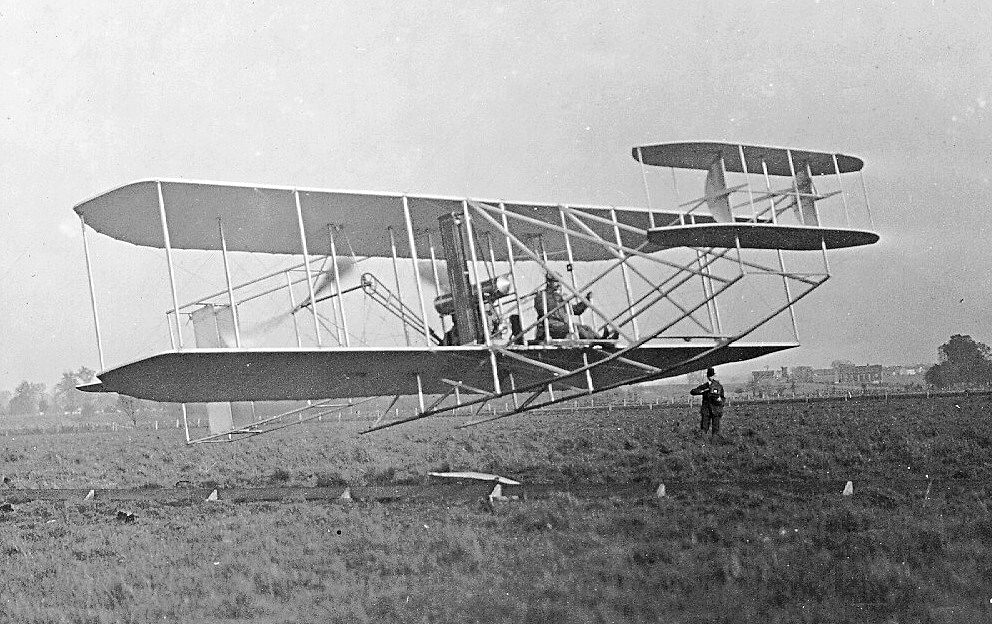

The Wright brothers get all the credit for the world’s first airplane. But behind the scenes on that December day in 1903 was another pioneer who was every bit as important to the mission, but far less celebrated — Charles Edward Taylor.

Taylor built the aluminum, water-cooled engine that gave flight to the Wright brothers’ dream. He was perhaps the world’s first aerospace machinist, and his ingenuity is still paying dividends today.

The Wright brothers and Taylor were pioneers in aviation. They understood that to get an aircraft in the air, every part and component of the aircraft would have to be designed and built with precision. And while the technology and materials have changed since that first flight, the science — and the importance of highly trained machinists — has not.

Today, aerospace machining combines the best of industrial machining with the best of precision science. It takes skill, ingenuity and a commitment to excellence. It combines the latest technologies such as computer numerical controlled (CNC) machining with reverse engineering and rapid prototyping. Aerospace machining touches every part of the aircraft— from the tail section to the fuselage to the landing gear and engine.

Imagine a 747 taking off without a landing gear, or an F-35 Lightning II without the parts and components to fire missiles. Neither would work, and no one would dare fly as a means of travel or defense. According to the U.S. Department of Transportation, major airlines serve nearly 50 million passengers a month. Next year, the U.S. military will gain a distinct advantage when the new F-35s roll off the line.

Yes, the world would be a much different place without aerospace machining and the constant innovation it lends to the industry. Industrial machining, with its focus on advanced engineering, has broken down the barrier of distance, made flight (as well as our world) a safer place, and helped the aerospace industry grow.

From high-precision plastic and metal prototypes to CNC machining, aerospace machining makes human flight possible. A lot has changed since the first flight in 1903 — machining has become more efficient and affordable — so to ensure you’re investing in the best tools for your next project, get a fast quote from PDS today.