Computer Numerical Ccontrol (CNC) machining is synonymous with precision and flexibility. It allows manufacturers to work with exotic materials, use a wide range of shapes and produce products with intricate parts, time and time again.

In fact, CNC machining is so common in today’s manufacturing world that it’s almost taken for granted. However, CNC machining processes require the right staff, the right machinery and the right tools.

Here’s a look at some of the computer controlled tools used in CNC machining:

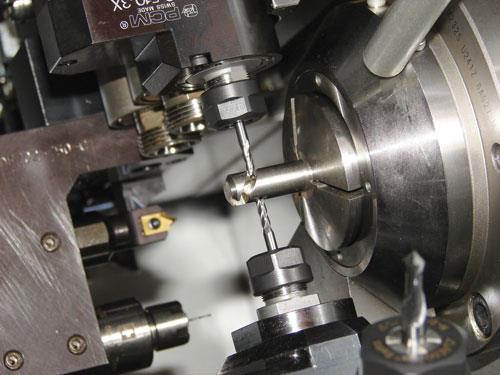

Drills used in CNC machining are not your ordinary, average drills. They’re precisely synced to a computer, which controls everything from the drills’ positions to the depth of the cut to the feed rate to the retraction.

Lathes spin parts in place while products are being cut, drilled, sanded, knurled or deformed. Their purpose is to ensure that waste and debris are removed from cuts and drill holes, so that each cut is exactly like the one that preceded it.

Electrical discharge machines are used to produce minute, complex cuts and contours in materials that would otherwise be very difficult to shape. Machines use a series of rapid-fire electrical bursts to melt or vaporize the material.

Milling machines are used to make shapes that have a high level of complexity from metals and other solid materials. The product is attached to a table and is then guided around a rotating cutter. In another application of the tool, a moving cutter operates across a stationary table. Milling machines are ideal for creating products that need to be three dimensional.

Plasma cutting machines use a computer-controlled torch to cut material. They’re often used to produce ducts and vents.

Water jet cutting machines are used to create an erosion-like effect on products. While it produces an effect that’s unique, it is not ideal for all products because many materials are impervious to the process.

Yes, there are a lot of tools that go into CNC machining, but it takes real experts with real, practical experience to truly understand the tools that make it happen. Contact Product Development Solutions today for more information, or to get a quote on your next project!