Manufacturing has seen the future. Like every other industry, advances in technology have changed manufacturing for the better. Machines are able to cut, turn and mill parts and components that are more intricate than ever. Furthermore, manufacturers are able to offer an unprecedented number of material options at an accessible price point.

None of these advances could have been possible without rapid prototyping. This technological advancement, without a doubt, has had the greatest impact on the manufacturing industry, especially in the automotive, aerospace and electronics market.

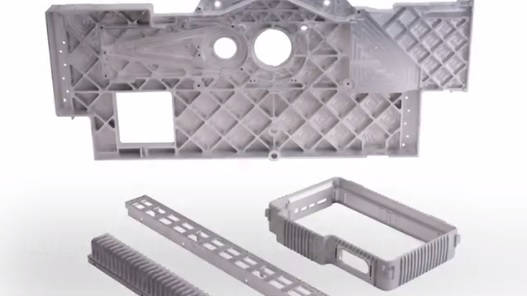

Implementing rapid prototyping using CNC machining makes the process of creating a viable prototype faster, less expensive and more precise. It also allows designers and engineers to create 2D and 3D prototypes with computer software. These digital prototypes can be examined from every angle and different tools can be considered. A big advantage of this technology is having the ability to test complex holes, slots and planes in a virtual environment.

Every step in the planning process — from determining how to clamp the material, to addressing the orientation of the geometric surface, to the tool-path planning — can be re-addressed at any given time. This allows designers and engineers greater flexibility in the prototyping process, which will more likely result in a successful prototype design.

Once the prototype design is approved, it’s then downloaded to the machine’s software, essentially automating the machining process and eliminating the risk of human error.

During the CNC machining process of rapid prototypes, a team of technicians, machinists, engineers and designers can rest assured that the prototype they’ll receive will be machined to precision. After all, every step of the process has been captured on computer software. Any errors or adjustments that need to be made can be done quickly without having to start over.

In a sense, everyone involved in the CNC machining process has a view of the future. They can see what the final product will look like well before the first cut is made. You can learn more about rapid prototyping and CNC machining by contacting the experts at Product Development Solutions.