In the past 15 years, the development of prototypes has changed significantly for the better. Rapid prototyping emerged with a big advantage over CNC machining from a speed perspective, but lacking when it came to accuracy and the ability to repeat parts. Rapid prototyping also had limitations in material property issues.

However, competition has driven both technologies closer together. As a result, CNC machining has become faster, while advances in software and 3D printing added more detail to rapid prototyping technology.

Deciding on which technology to use only becomes more difficult with this new competition.

The Case for CNC Machining

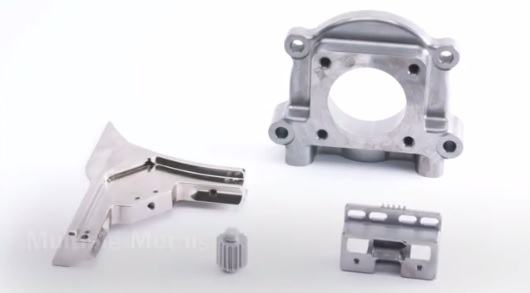

CNC machining can handle a virtually unlimited range of materials, and in some cases, machines can be made large enough to handle aerospace parts. However, when CNC machining processes accommodate more complex designs, the cost and time spent rises, along with needed tool changes and multiple setups.

Two more distinct advantages for CNC machining involve precision and repeatability. CNC machines deliver precision down to .0005 inches with the right machine. Rapid prototyping has closed this gap recently, but CNC is still the most precise process. Secondly, its repeatability is also superior to rapid prototyping if the tools and materials are unchanged.

Rapid prototyping advantages

Rapid prototyping allows for extreme flexibility in design. Basically, if you can imagine it and draw it up within the software, you can bring that prototype to life. You can also increase complexity without adding much cost either.

Cost effectively producing complex parts is by far the biggest benefit of rapid prototyping and the reason it was developed in the first place.

The people (or lack thereof) using rapid prototyping is another big advantage of this process. Designing components became much simpler with this technology; therefore, the skill set required became much more attainable. Furthermore, rapid prototyping requires much less attention from your staff during the build. You can deliver the files for part production and start building right away.

Product Development Solutions can help you figure out any technology conundrums. Contact us today, and get started with one of our fast quotes.