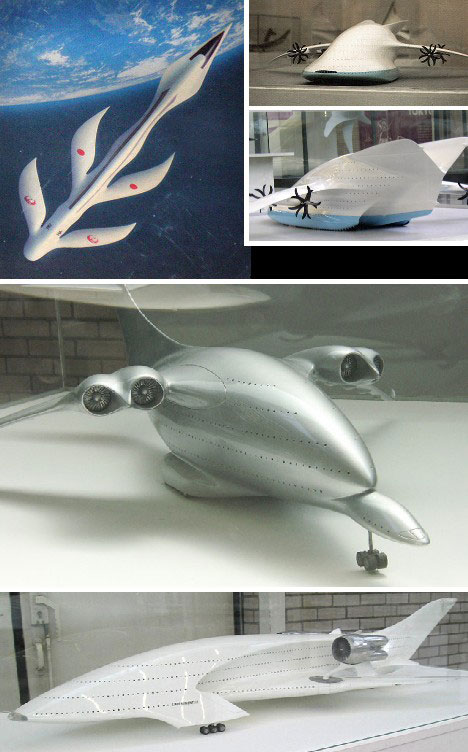

Innovative airplane designs have revolutionized flying. They push aerospace innovation to the limit, expanding the realm of possibility while at the same time proving the necessity of the practical.

Some of these designs carry names like The Flying Ram and the Avro Arrow and are built with “smart wings” that change shape to optimize flying conditions. These are, of course, airplane prototypes that wouldn’t be possible without cutting-edge technology and materials provided by aerospace equipment manufacturers.

The manufacturing process plays a critical role in getting airplane prototypes off the ground and, hopefully, to the marketplace. It’s a complicated process with several tracks running on parallel time frames. It involves planning for the known, as well as the unknown.

Computer numerical control (CNC) machining is a key element to the success of any airplane prototype. The machining process starts with a digital design, which allows for virtual process modeling and simulation, as well as any immediate adjustments for specifications and materials.

Once a design is agreed upon, tooling, machining and assembly begins. It’s faster and less expensive than more traditional types of manufacturing, so different materials can be tested for stiffness, strength and their abilities to withstand real-world conditions, both expected and unexpected.

The relatively fast turn-around time allows engineers to perform evaluations at the same time they’re considering cost, overall performance and different materials and designs. If it the idea works, the prototype airplane can move forward. If it fails (and they sometimes do) all is not lost.

The digital design can be quickly changed, and new materials can be explored, from the standard to the exotic. As a result, another small quantity of the prototype can be produced — from one to 1,000 — and the process can begin again.

Overall, CNC machining plays a critical role in the design process of airplane prototypes and in making flight safer and more efficient.

Where will the next futuristic flying machine come from? Only the inventors and engineers with their heads in the sky know for sure. But one thing is certain; world class aerospace equipment manufacturers will play a key role in making these dreams a reality.